Plug Weld Design - This is applicable for the load putting the weld in shear. Plug Weld Used to Attach Staybolt in Pressure Vessel Fabrication.

Chapter 22 Welding Representation 1 Importance Of The

Perpendicular Plug Weld Joint.

Plug weld design. My answer is 1 plug welds are considered CJP 2Your minimum WPS plate thickness should be 12 thk. The location will be indicated by a centerline through. Unless lateral deflection of the parts is prevented they shall be connected by at least two trans-verse lines of fillet plug or slot welds or by two or more longitudinal fillet or slot welds.

A plug weld is used to fasten two pieces of metal together using a welder. The ASD allowable strength equals FwΩ. Most of these terms and potential issues will be taken care of by the manufacturing factory involved in the project but it is important for a design engineer.

Humanengr Structural 21 Oct 15 1336. The edge weld is a specialised weld that has limited fields of application and is mostly used for the joining of sheet metal components although it may be used for the fabrication of tube to tubesheet welds. Be sure you will get the best out of more than 4000 used machines and tools.

Be sure you will get the best out of more than 4000 used machines and tools. DESIGN GUIDE ON WELDING. NBEEBE If youre using AWS D11 Structural Welding Code Refer to Sections 2453 and 2454.

Comparative stress for all types of plug and spot welds where. 8mm 225tw tp thickness of the plate containing the plug The LRFD design strength of a plug or slot weld is equal to its design stress ΦFw times its area in the shearing plane. Welds which occur on opposite sides of a common plane shall be interrupted at the corner common to both welds see Figure 212.

Plug Weld Joining Two Plates c. Weld Design Menu The following are recommended values for weld joint coefficient conversion. Diameter of plug hole D tp 516 in.

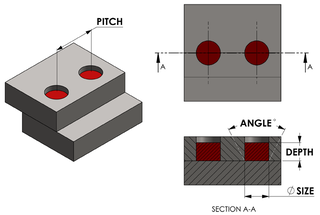

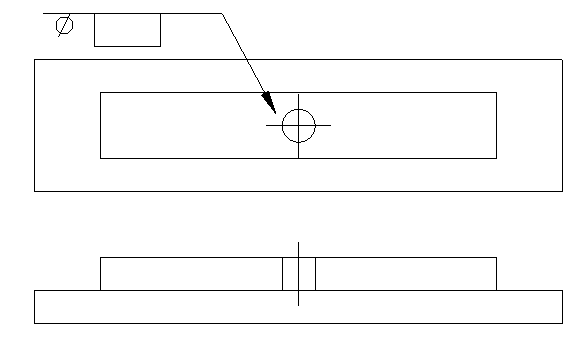

Plug Weld Reinforcing Joint Primarily Attached by Fillet Welding. The plug weld symbol is a rectangle with a diameter symbol placed to the left of the symbol as well as the number associated with that diameter. 26 Plug and Slot Welds Depth of Filling Diameter Space Length Width Table 21 Minimum Diameter of Hole for Plug Welds or Width of Slot for Slot Welds C-26 Plug and Slot Welds Technique for Flat Vertical or Overhead Position 3153 Qualification of any groove weld CJP PJP or fillet weld procedure qualifies any WPS.

All welds in the construction industry. A plug weld joining two pieces of sheet metal together. But there is a lot to be said for the welding procedure.

This is a poor idea. When joining the pieces a hole is drilled into the top piece and it is laid over the bottom one. In this chapter the behaviour and design of welded connections under various static.

Type of Weld Loading Coefficient of Weld joint butt1 Compression 100 Tension 85 9002 1003 Shear 70 Fillet. May be tempted to use a plug weld in the base plate to weld on to the end of the anchor rod. When there is insufficient.

Ad At Surplex you will find used machinery and industry equipment at best prices. The Lincoln Electric Companys Duane Miller one of the na-. Hole Beveling When Plate Thickness is Over 1inch and Hole Diameter is Less Than 1 inch.

Ad At Surplex you will find used machinery and industry equipment at best prices. The effective area of the plug or slot weld is generally equal to the area of the hole or the. PlugSlot Weld Strength Calc.

3 The symbol should be plug weld not fillet weld. Plug welds are intended to be loaded in shear not in tension. Table 42 WPS Qualification-CJP Groove Welds- Test on plate 38.

A weld is then made by running a bead inside of. For Groove weld operator qualification it is 2T of test plate. Some drawings will not indicate the hole in the print so the use of dimensions come in to play when locating where a plug weld will be executed.

The balance 5 is made up by plug slot and spot resistance welds. AWS D11 06 C-5265 describes a technique that is much better than the swirl the electrode. τ Z shear stress in the weld base area MPa psi τ 0 shear stress in the weld peripheral area MPa psi α conversion factor of weld joint - Plug weld - perpendicular Shear stress in the weld base area Shear stress in the weld peripheral area where.

As metengr has stated they can be treated like a fillet weld. The final three weld types to be dealt with in this series on weld design are the edge weld the spot weld and the plug weld. Fig3 Partial penetration weld 222 Design The butt weld is.

The term weld brings with it weld process type of weld joint filler metal heat affected zone and material temper porosity distortion material shrinkage structural integrity etc. In last threelectures we have discussed about fillet weld and then butt welds and I have told that threetypes of welds are there fillet weld butt weld and plug weld or slot weld now plug weld andslot weld is nothing but a type of fillet weld. Video 1 Hello I am going to discuss about the design of plug and slot weld.

F acting force N lb d diameter of plug weld mm in i number of welds. Plug welds are there own unique item.

Welding Symbols Engineering Design Technology

Welding Representation Ppt Video Online Download

Effect Of Wire Selection On The Weld Appearances Of Cmt Plug Welded Download Scientific Diagram

Plug Weld Check Structural Engineering General Discussion Eng Tips

Plug Weld Check Structural Engineering General Discussion Eng Tips

Weld Joint Geometery And Welding Symbols Terminology Definitions

Perpendicular Shear Stress For Plug Weld Joint Equation

Me 330 Manufacturing Processes Welding Processes Cont Ppt Download

The Friction Plug Welding Steps A With The Utilization Of The Chuck B Download Scientific Diagram

Plug Weld Symbols Interpretation Of Metal Fab Drawings

Types Of Welds And Joints Plug Weld Slot Weld Autogeneous Weld Homogeneous Heterogeneous Welding Youtube

Welding Symbols

Welding Symbols Iso 2553 And Weld Joint Design

Deciphering Weld Symbols Millerwelds